Our Lab

In our lab, raw materials are to be examined and measured, new products to be tested by sample and by batch, and the life circles of finished products to be detected, guaranteeing the development of new products and the good control of production quality.

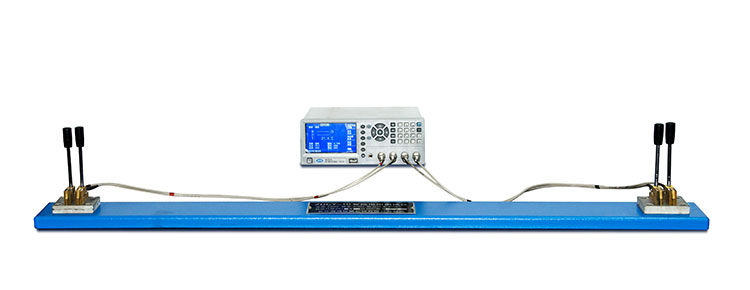

Intelligent Resistance Tester

Used to measure the resistance value and the resistance rate of copper wire and copper-clad aluminum wire, to strictly control the quality of materials

UV Accelerated Weathering Tester

Used to detect our products in the accelerated weathering environment by artificially simulating the UV radiation of natural sunlight, to acquire the measurements of their anti-weathering ability, so as to determine their life circle

Salt Spray Corrosion Test Chamber

Used to test the ability of anti-salt-spray-corrosion of materials and metal jacketing in practical environment through artificial simulation of salt spray, to determine the life circle of our products and where they can be applied

Elongation & Tensile Strength Tester

Used to test the elongation and the tensile strength of such metal materials as copper wire and copper-clad aluminum wire, to ensure the quality of materials, the improvement of processing technology, and the enhancement of efficiency

Multifunctional Solid Density Tester

Used to detect the density and the mixing ratio of such materials as plastics, rubber, copper, aluminum and alloy, to ensure the suitable choice of raw materials

Rubber Sclerometer

Used to examine the hardness of plastics and rubber in different seasons, to determine the proper application of raw materials